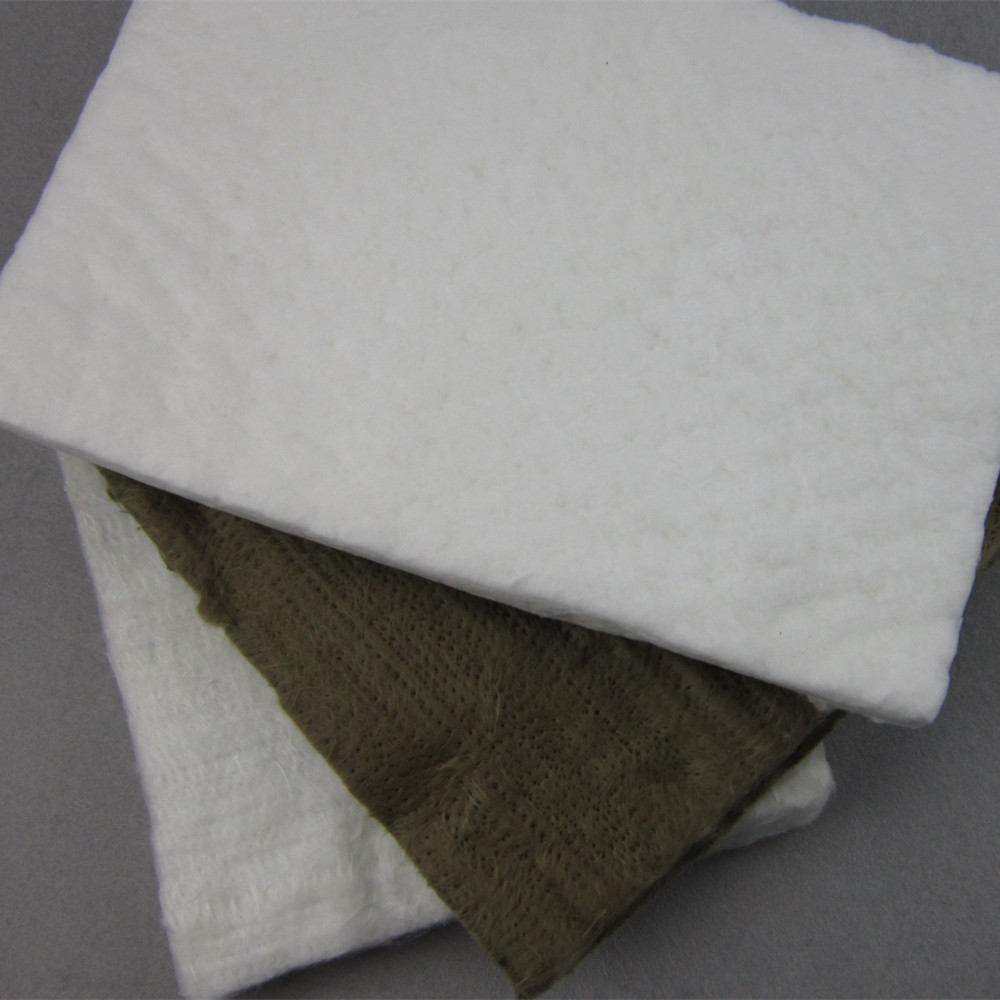

Base de material : Fibras de sílica amorfa pura (≥96% de conteúdo de SiO₂), processadas em uma estrutura densa e agulhada.

Desempenho térmico :

Uso contínuo : 1000°C (1832°F), com tolerância de curto prazo de até 1260°C (2300°F).

Contração linear mínima (<2%) a 1000°C, garantindo estabilidade dimensional a longo prazo.

Principais vantagens :

Quimicamente inerte: resistente a ácidos, álcalis e oxidação, mesmo em calor extremo.

Condutividade térmica ultrabaixa ( 0,035–0,045 W/m·K ) para retenção superior de calor.

Não combustível (classe A de incêndio) e zero emissões voláteis.

Casos de uso típicos :

Componentes de escape de alta temperatura (turbocompressores, cabeçotes, sistemas de escape de corrida).

Blindagem térmica crítica em aeroespacial, fundições e geração de energia.

Base de material : Fibras de vidro tipo E (vidro de aluminoborosilicato de cálcio) unidas em uma manta flexível.

Desempenho térmico :

Uso contínuo : 450–550°C (842–1022°F), com algumas notas modificadas sobrevivendo à breve exposição a 700°C (1292°F).

Principais vantagens :

Custo-benefício: ~50–70% mais barato que soluções à base de sílica.

Excelente absorção sonora (NRC 0,65–0,85) para redução de ruído em sistemas de exaustão.

Fácil de cortar e moldar para se adaptar a superfícies irregulares (densidade: 60–100 kg/m³).

Limitações :

Fragilização gradual das fibras acima de 500°C, com risco de liberação de partículas.

Potencial liberação de formaldeído em ambientes úmidos e de alto calor (requer certificação UL GREENGUARD).

| Parâmetro | Tapete de agulha de sílica | Tapete de agulha de fibra de vidro |

|---|---|---|

| Temperatura de pico | 1260°C (2300°F) | 700°C (1292°F) de curto prazo |

| Condutividade térmica | 0,035–0,045 W/m·K | 0,05–0,08 W/m·K |

| Resistência química | Excepcional (pH 1–14 estável) | Moderado (degrada-se em ácidos fortes) |

| Amortecimento Acústico | Limitado (NRC 0,3–0,4) | Alto (NRC 0,7–0,85) |

| Vida útil a 600°C | 10+ anos | 2–5 anos |

Escapamentos turboalimentados/diesel :

Use tapetes de sílica perto de turbos/DPFs onde a temperatura do gás exceda 800°C.

A fibra de vidro é adequada para escapamentos/silenciadores (<500°C).

Designs sensíveis ao peso :

Sílica: Custo mais alto, mas 30% mais leve que as alternativas de fibra cerâmica.

Fibra de vidro: econômica para zonas térmicas não críticas.