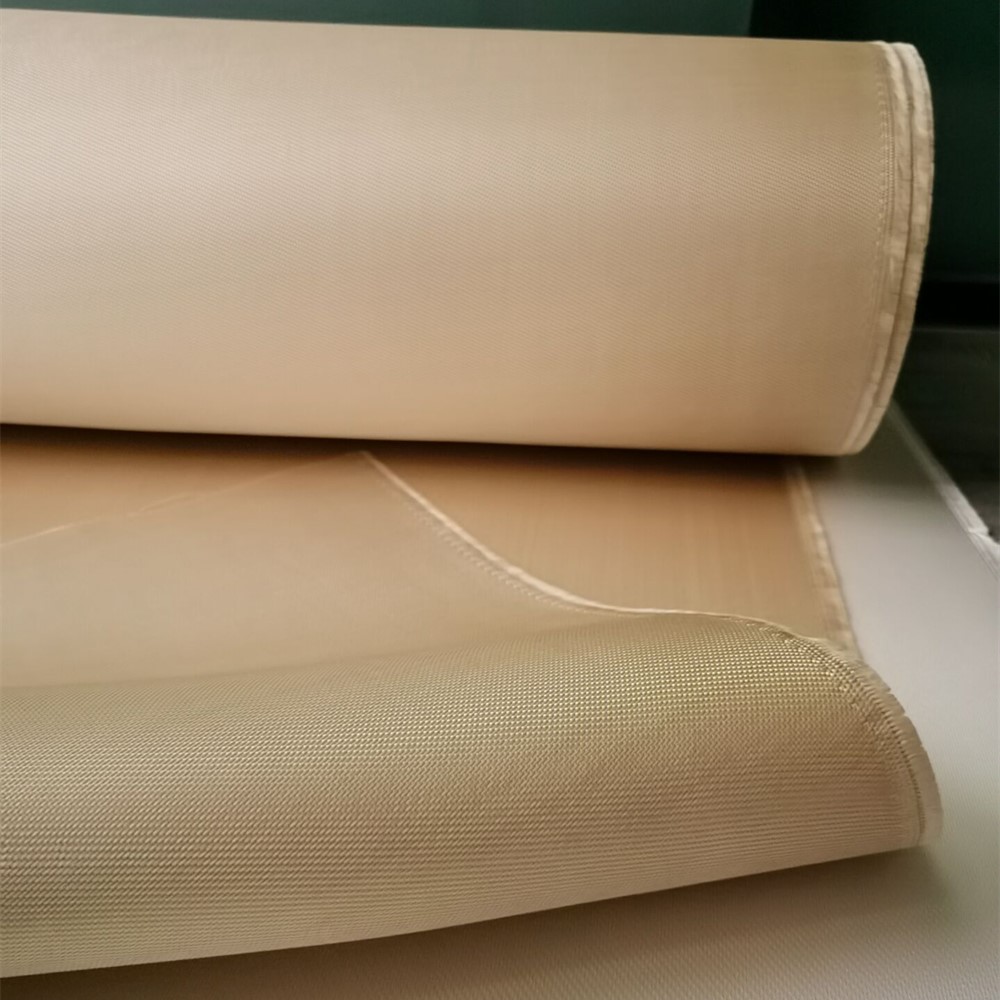

Tecido de sílica tecido é um excelente material para uso em mantas de soldagem devido à sua resistência a altas temperaturas, durabilidade e n、o inflamabilidade. Aqui está uma vis、o geral de por que o tecido de sílica é a escolha preferida para mantas de soldagem:

Resistência a altas temperaturas:

O tecido de sílica pode suportar temperaturas de até 982°C (1800°F), tornando-o ideal para proteger superfícies e trabalhadores do intenso calor gerado durante as operações de soldagem.

Isolamento térmico:

O tecido possui excelentes propriedades de isolamento térmico, proporcionando uma barreira contra a transferência de calor. Isso pode ajudar a evitar danos aos equipamentos ou materiais circundantes.

Resistência à chama:

A sílica é naturalmente resistente a chamas, tornando-a adequada para ambientes onde há presença de faíscas, metal fundido ou escória quente.

N、o abrasivo:

Ao contrário de alguns outros tecidos de alta temperatura, a sílica tecida n、o é abrasiva e é macia ao toque, o que evita danos ao material soldado ou às superfícies circundantes.

Durabilidade:

O tecido de sílica é muito durável e resistente ao desgaste, mesmo sob condições desafiadoras de ambientes de soldagem. Também é resistente à degradaç、o UV e manterá seu desempenho ao longo do tempo.

Resistência Química:

A sílica é resistente à maioria dos ácidos e álcalis, tornando o tecido ideal para ambientes com exposiç、o a produtos químicos ou substâncias corrosivas.

Leve e flexível:

O tecido de sílica é relativamente leve, o que facilita o manuseio e a instalaç、o como manta de soldagem, ao mesmo tempo que oferece alta proteç、o contra calor e faíscas.

Resistência Ambiental:

O tecido de sílica também pode suportar a exposiç、o à umidade sem perder significativamente suas propriedades isolantes.

Tecido de sílicaé um material altamente eficaz para mantas de soldagem, oferecendo excelente resistência ao calor, retardamento de chama, durabilidade e resistência química. É uma escolha valiosa para aplicações industriais onde a proteç、o térmica elevada é crítica.